Eyewash Station Inspection Template

Rasshifrovka shtrih koda tovara. So, after offering good eatables to the Lord, the devotee takes the remnants, called prasadam. On the other hand, a person in Krsna consciousness knows how to use everything in the service of the Lord; therefore he does not become a victim of material consciousness. For example, for an impersonalist, the Lord, or the Absolute, being impersonal, cannot eat. Thus everything becomes spiritualized and there is no danger of a downfall. Whereas an impersonalist tries to avoid good eatables, a devotee knows that Krsna is the supreme enjoyer and that He eats all that is offered to Him in devotion.

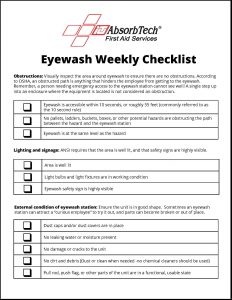

Eyewash station weekly checklist (PDF) helps ensure eyewash stations are working. ANSI recommends that you inspect your eyewash stations weekly. Does the eyewash station show any physical signs of chemical contamination? Contact EHS/Facilities Eye Wash Station Inspection Record Initials Week # / Date 1.00.

Emergency Eyewash Station If you are responsible for conducting eyewash station checks at your facility, we recommend using an. An eyewash station checklist can have numerous benefits: • Ensure the unit is working properly in a time of crisis • Streamline the inspection process • Ensure a consistent and thorough process • Help your facility meet OSHA and ANSI standards. As the designated safety inspector, you should be trained and/or certified in the appropriate OSHA and ANSI standards. You should also stay up-to-date with any new regulations or standards. ANSI recommends that you inspect your eyewash stations weekly. Compliance Both OSHA and ANSI have requirements for eyewash stations. OSHA is considered the enforcement agency, while ANSI sets the standards.

In the case of eyewash stations, OSHA references the ANSI standard, but they do not require compliance with it. In order to meet best management practices, a good safety program will follow both the OSHA and ANSI standards. OSHA 1910.151(c) states the following regarding eyewash stations: That where the eyes or body of any person may be exposed to injurious corrosive materials, suitable facilities for quick drenching or flushing of the eyes and body shall be provided within the work area for immediate emergency use. OSHA further elaborates on the work conditions that would require an eyewash station or shower in a Letter of Interpretation dated April 14, 2008. The American National Standards Institute’s emergency eyewash and equipment standard (ANSI Z358.1-2014) sets the standard for proper eyewash equipment selection, installation, operation, and maintenance. The eyewash station checklist below covers key points in the ANSI standard in the areas of operation and maintenance.

The checklist assumes the unit has been properly selected and installed. Refer to the manufacturer’s guidelines if you are installing an eyewash unit yourself. Great care should be taken when determining the distance from the hazard, any possible obstructions, such as stairs or doors, and height/accessibility requirements. Eyewash Station Maintenance Checklist Complete this weekly for each eyewash station at your facility. In order to ensure a successful eyewash program, you should conduct an annual audit to make sure all stations are in compliance. You should also audit the program any time new work hazards are introduced or relocated within your facility.

Eyewash Station Training All employees must be familiar with the location and use of eyewash and safety showers, even if their job does not involve working directly with toxic or corrosive chemicals. You may be called upon to aid a fellow employee who has had an exposure. Cccam to oscam converter 12 download pc. Eye and Face Protection – Eyewash Station Training Points • Hold eyelids open using the thumb and index finger to help ensure that effective rinsing has occurred behind the eyelid. It is normal to close eyes tightly when splashed, but this will prevent water or eye solution from rinsing and washing the chemical out. • Eyelids must be held open.